|

|

Post by decieved on Mar 31, 2016 8:59:55 GMT -5

Great forum many interesting build threads. Heres pictures from my ongoing build, inmyspare.tumblr.com/ (if you like light builds you might wanna stay away  ) |

|

2rike

Full Member

Posts: 184

|

Post by 2rike on Mar 31, 2016 16:05:49 GMT -5

Like the progress so far, like you say its chunky but each to there own, its a lot better to be over engineered and safe than flimsy. Have you been on the build long? please share your build photos as you go!

|

|

|

|

Post by decieved on Apr 3, 2016 1:22:52 GMT -5

Yeah its chunky allright, i might redo the frame somewhat lighter when all is figured out. I estimate that the finished frame will weigh in around 40kg i think thats about 80-100pounds. Looking at similar trikes like the can am spyder that weighs in at 400kg(not sure where it all goes) that would mean if im taking 1/3 off the thickness out of my frame tubes i would come in at 390kg instead of 400kg. I also ran fea on a lighter frame and it flexed and deformed to much for my liking but then again i may have loaded the frame to much. I havent been on it that long just a couple of weeks, labor is quick figuring everything out is not  Right now im trying to work out my seating and where my legs shall go. One thing determening the looks of the rearend is how much suspension travel im going for, what do you guys think/run with im thinking travel in bump? Is there a build on here with motorcycle seating/steering? |

|

|

|

Post by decieved on Apr 10, 2016 6:31:39 GMT -5

Some minor progress, next up is turning bushings and mounting the front wheels to start tackle steering and suspension i think. |

|

|

|

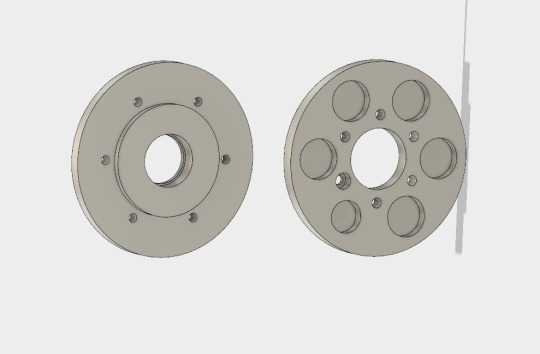

Post by decieved on May 3, 2016 12:06:55 GMT -5

I made some rod ends to use in my suspension. I havent seen anyone use rubberlike bushings when going for a pushrod/bellcrank suspension, i guess it will give more friction and some flex time will tell if i need to switch em out. |

|

|

|

Post by Liteway on May 3, 2016 14:00:32 GMT -5

Thanks for posting the build.

Why not use conventional rod ends? Cheap, reliable (when used as the engineering intended), and slop free.

On my trike, I first replaced the used up needle bearing sets on the inboard ends of the A-arms with neoprene bushings. Changes in caster and toe were visible under heavy braking. You could actually see the hub mounted fenders rotating forward, not the best thing for stability. They were replaced with proper needle bearing sets.

The eyes in my front shocks were rubber (or some variation) with metal inserts. As used with bellcranks instead of what they were designed for, the increased rotation required caused a lot of stiction, enough that the trike would not return to the same height when loaded and then unloaded. I replaced those with needle bearings also.

I know these are not the specific applications you are talking about, but why not go with a low friction deflection free alternative when available?

I suppose rubber would impose less ride harshness if that is a concern.

Anyway , nothing wrong with experimenting. Its what we do.

Thanks for pics and looking forward to seeing your progress.

|

|

|

|

Post by decieved on May 4, 2016 2:11:00 GMT -5

The local MOT doesnt like rod ends, they are not banned but its not uncommon that they break and wear rapidly. Another way is to use a stiffer rubber or even plastic/metal bushing. Started on my rear swing  Made a suspension rocker  |

|

|

|

Post by decieved on May 4, 2016 3:20:13 GMT -5

You know what  im gonna go with spherical bearing rod ends after all for the suspension pushrod links and coilover. |

|

|

|

Post by noahkatz on May 7, 2016 15:54:34 GMT -5

I also ran fea on a lighter frame and it flexed and deformed to much for my liking but then again i may have loaded the frame to much. ever heard of triangulation? |

|

|

|

Post by decieved on May 11, 2016 19:44:15 GMT -5

Yes i have, it made little difference. Welded and mounted the swing.  Cush drive  One piece rear axel im gonna try to make once the mailman delivers my brake.  |

|

|

|

Post by noahkatz on May 13, 2016 16:18:40 GMT -5

Yes i have, it made little difference. Then you didn't do it correctly. Triangulating a 4-sided structure with a diagonal will increase in-plane* stiffness by orders of magnitude. * It will increase torsional stiffness only marginally; high torsional stiffness requires a 3D structure, like a tetrahedron. |

|

|

|

Post by decieved on May 14, 2016 10:14:37 GMT -5

I added what could be added without obstructing anything else, and only to the frontend.

It sure helped but in the end it wasnt enough and thats only because i added to much load.

For the midsection of the frame, what is now just a big square there aint room for anything so i wanted some heavy lower rails to take most of the loads.

I might redo the frame once i have everything worked out.

|

|

|

|

Post by decieved on Jun 2, 2016 10:56:56 GMT -5

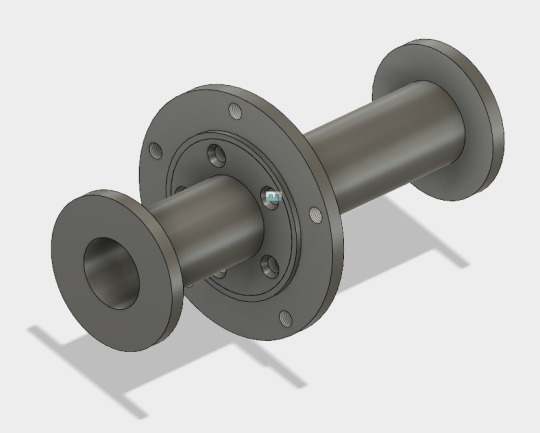

I havent recieved my brake caliper yet but i went ahead anyway and made my rear hub.   |

|