|

|

Post by hydrojim on Dec 1, 2012 1:08:16 GMT -5

Hi, this is my first post on this forum and what better way to start than introducing my project. Unlike some of the performance based trikes, mine is being built for the purpose of fuel economy. I'm currently in the design stages, and figured I could use some input from people who have been there and done that. The Goal of my project is to create a 1 seater reverse trike capable of 125 MPG while cruising at 65 mph utilizing no fuel source other than standard gasoline that you would find at your local gas station. And, my budget is set at $5000 which makes things really tight if not impossible. Parts List: Donor Bike: Kawasaki Ninja 250R EFI conversion: Ecotron ninja 250r conversion kit Window: F16 replica canopy from Todd's Canopies Spindle/Bearing/Rotor Kit: Mustang 2 drop spindle kit off ebay Here are some pictures of the vehicles that inspired me so that you have a better idea of what I'm trying to accomplish     That's all I've got so far. The only components of the vehicle that I still have major questions about are the Front Suspension, Sealing the window, and the shifter mechanism. The biggest one is the suspension. It seems there are so many ways to do it, but I'm looking for the quickest and most cost effective one. |

|

|

|

Post by hydrojim on Dec 1, 2012 10:46:20 GMT -5

I plan on attaching the window they way this one is attached:  That way, when it's hot I can take the canopy off and the front windscreen will still be in place. This is supposed to be a fun project to drive around in, so most of the time I won't be trying to achieve maximum MPG. I haven't gotten a quote, but a guy who bought the F16 canopy from todds canopies a few years ago said it cost him $350. That's not bad considering buying my own sheet of polycarbonate would be half the price and I would still only have a flat window which I don't want for aerodynamic reasons. |

|

|

|

Post by srx660 on Dec 2, 2012 6:44:28 GMT -5

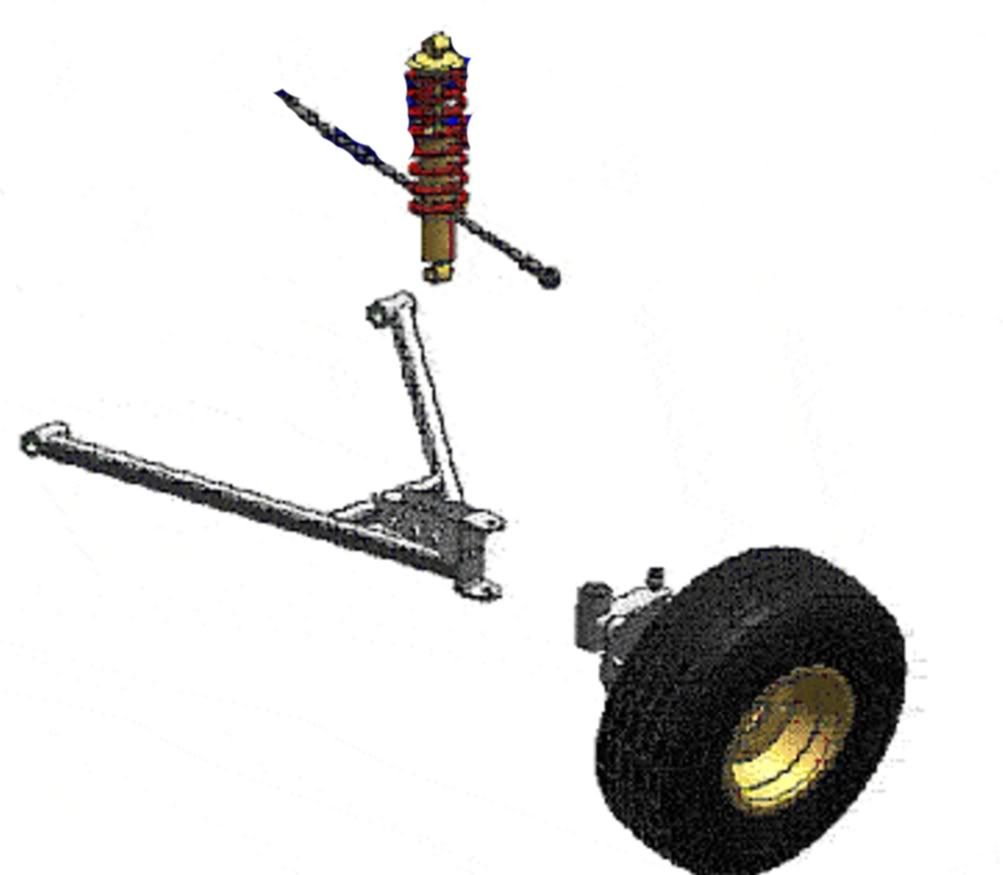

Something to think about is using the most simple suspension you can make. To me a off-road 3 point suspension modified for the street is the cheapest and easiest. Now i would NOT use this suspension with flat treaded tires, but motorcycle type tires would work without changes to the tire to ground contact patch.  This suspension is not for high speeds on the road. If you want that i would build a double a-arm suspension like the Locost website has for their lotus seven replicas.   www.locostusa.com/forums/index.php www.locostusa.com/forums/index.php SRX660 |

|

|

|

Post by fredvv44 on Dec 2, 2012 11:56:34 GMT -5

it is my understanding that some states won't allow the use of off road components on a street car. i don't know if that applies to home fabricated pieces and some states don't allow that either. Florida requires the front uprights to be from a street car.

Fred V

|

|

|

|

Post by hydrojim on Dec 2, 2012 14:56:07 GMT -5

For aerodynamic reasons, I'm looking to build a suspension like this one:  Would using Rod-ends be acceptable for attaching the control arms to the chassis? How do I know what strength springs I need? |

|

|

|

Post by fredvv44 on Dec 2, 2012 19:03:09 GMT -5

Jim, that is a double wishbone with pushrod springing. that can be complicated when choosing the spring rate as the bell crank lever ratios come into play. att he speeds you will be driving a simple coil over shock external would be much worth considering.

front suspension design is a whole study in it's self and there are several simulator programs available for free to test your design. i cannot say this in any stronger terms that you MUST study suspension design or you will end up with a car that is un-driveable.

Fred V

|

|

|

|

Post by hydrojim on Dec 2, 2012 21:38:15 GMT -5

fredvv44- an effort to reach minimum drag, an external shock is not acceptable for my application. I will admit it would make things much simpler though. Guess I better start studying.

|

|

tryota

Junior Member

Posts: 62

|

Post by tryota on Dec 2, 2012 23:57:14 GMT -5

Hey have you seen the reverse trike from fuel tech. its enclosed and they get 92 mpg with a honda engine 15oohp.

|

|

tryota

Junior Member

Posts: 62

|

Post by tryota on Dec 3, 2012 0:00:56 GMT -5

Ive just joined also this is really cool hope to make a lot of friends and share our Ideas and dreams with all. Our Goververment bail out the car industry yet I did not see any go to the Auto lite car or Pulse what ever the call it only built 325 of them and they got 100 mpg , design by Jim Bede.l

|

|

|

|

Post by hydrojim on Dec 3, 2012 17:06:41 GMT -5

Thanks for the input everyone. I did not realize the mustang front end parts were so heavy. I'll definitely have to look for lighter parts. My chassis is going to be built out of steel because. I'm trying to keep the budget for this build under $5000, so steel is my only option. I'm only 16 working part time so $5,000 is the money I can have saved up from work by next summer which is when I want to start the project. The body will be fiberglass over a foam core because it allows me to get the compound shapes I want with the lightest weight. As far as the front end goes, how would I go about doing something like this guy did(referring to the motorcycle wheels and brakes):  I wouldn't mind using mechanical(non power assisted) brakes too because it would eliminate some complexity and cost from the vehicle and with it being so light, I don't think there would be any safety issues. Let me know what you guys think. |

|

|

|

Post by fredvv44 on Dec 3, 2012 19:00:34 GMT -5

motorcycle wheels are designed for radial loading only so they use regular ball bearings. cars have side loads against the wheels and require taper bearings to take the load. i guess if the car is light enough the bike wheels may be OK.

just my 2 cents.

Fred V

|

|

|

|

Post by hydrojim on Dec 3, 2012 19:07:28 GMT -5

I thought about this, but this car isn't meant to be a daily driver. Just a fun project to see what the maximum MPG I can achieve is. And the rear end is going to be a motorcycle wheel already so that one is going to have wear problems too.

I have to figure out how I'm going to do it first!

|

|

|

|

Post by hydrojim on Dec 26, 2012 12:41:15 GMT -5

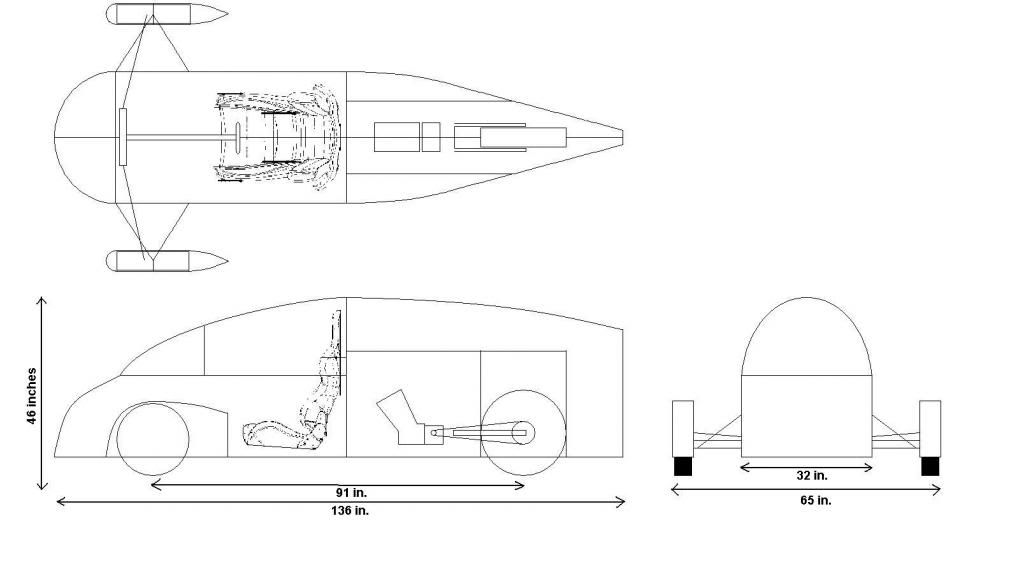

Figured I'd post a quick update as to where I am in the design process. Construction is slated to start During Summer of 2013 and I hope to finish the project by the end of the summer. In the meantime, I'll work on collecting parts for the project and work out any design kinks My budget of $5000 is still standing strong. Current estimated cost breakdown: Kawasaki Ninja 250R: $1000 Ecotron EFI kit: $600 Chassis steel: $500 F16 canopy: $400 Steering Rack: $250 ATV spindles, Hubs, Rotors, Calipers $200 Total: $2950 so that leaves me with $2000 for the rest of the stuff which I’m not particular about. It will be whatever I can find for the cheapest that will do the job. Estimated costs of these parts: Shocks: $100 Ball Joints: $50 Tie rod ends: $50 steering wheel: $50 racing seat: $100 5-point harness: $80 Lights: $60 EGT sensor(for lean burn tuning) $100 Push Pull cable for shifter $50 Brake, Clutch, and throttle pedals 4x110 to 4x100 wheel adapters $50 Civic VX wheels $150 2 Tires 155/80R13 $100 upper and lower control arms $50 pushrods for suspension $20 A lot of this is just estimates, but I have $1000 of wiggle room based on these numbers. This money will be use for paint, misc. hardware, and anything else I need. Here is my design as it sits now.  The specifications are just guesses because I don't have any of the parts with me to take measurements. I would like to make the car thinner and shorter. shorter is easy to achieve by reclining and the major factor in the width is the canopy width. The current design gives me a frontal area of 9 square feet. combined with a estimated drag coefficient of .16, this gives a CdA of 1.44 which is pretty good! a 2nd seat could also easily be added by extending the length of the trike. I'm not doing this for cost and time reasons, but it wouldn't affect efficiency too much and would make the vehicle a little more practical. The only thing I haven't completely figured out yet is the brakes. The front will have 2 calipers from an ATV and the rear will be the brake caliper from the ninja 250r. I'll need to figure out how to get the right size master cylinder so if anyone knows how to help on that front, let me know. My next step is to start coming up with the chassis design. I think the main passenger compartment will be made of square tubing for simplicity and squareness, but things like the roll bars and bracing will be made from round tube. Then, I'll get an estimate of my final weight and see if I'll need to change my drive train to a more powerful one. |

|

|

|

Post by DaveJ98092 on Dec 27, 2012 0:16:17 GMT -5

Jim, take a peek at the Evo-Exo's suspension. www.eco-exo.com/gallery_3.html It is a very light set up. It does not use a rack but instead it uses a long tab that offsets the linkage to the way you want to go. I know it will pass most states requirements. This trike kit uses a Suzuki Burgman 400cc scooters engine and CVT transmission. Single cylinder is more than enough to push a light trike up to 100 MPH. If the right (DR Pully brand) CVT sliders are used you can adjust the overdrive ratio some. Some Burgman 400 owners get 75 to 80 MPG. This kit weighs about the same as the complete bike but the trike is more aero. |

|

|

|

Post by hydrojim on Dec 29, 2012 22:39:38 GMT -5

Does anyone know of a way that I can use a car tire on the rear of the trike? I'm looking for something thin for rolling resistance reasons, but the idea of using a car tire sounds better than using a motorcycle tire to me. If anyone knows how to go about doing this, let me know

|

|

|

|

Post by captainamerica on Dec 30, 2012 3:38:51 GMT -5

Well a motorcycle rim can handle a car tire just fine, its what I am using. My tires are 205s which is 8 inch width on a 7 inch rim. But you can go smaller, if you are using a smaller bike as a donor which I presume you are you may have a really thin rim, you can get like a 145 on there. A motorcycle shop should be able to mount it for you, my local shop did it for cash no receipt for liability reasons.

|

|

|

|

Post by DaveJ98092 on Jan 5, 2013 17:33:45 GMT -5

Jim I am running a 165/65 SR 15 on my scooters rear that was factory 160/60 HR15. They fit tighter as a motorcycle 15 inch rim is slightly larger diameter than a cars 15 inch rim. It just means the bead sets deeper in the rim by like 1/8 inch. Not a biggy. Coker tire has some differnt sizes too. www.cokertire.com |

|

|

|

Post by hydrojim on Jan 23, 2013 18:04:16 GMT -5

I've reconsidered my choice for ATV parts. the steering arm is on the wrong side, so I couldn't put the steering rack where I wanted. Not to mention, they're not exactly ideal for a car application. I'm thinking using citroen 2CV wheels will give me the small and thin wheels I'm looking for. Only problem is they have a weird bolt pattern size, so I'll have to make my own uprights/spindles unless I can find something that will work.  |

|

|

|

Post by joeld0803 on Jan 23, 2013 19:42:32 GMT -5

As long as the center of the rim is fairly solid you could buy a wheel spacer and trace the pattern to the rim once "centered" up properly and redrill the pattern to what you need and then rebore out the center to the necessary size to fit the hub of choice.

Just a suggestion if you already had a particular spindle in mind.

|

|

|

|

Post by hydrojim on Jan 23, 2013 20:44:25 GMT -5

I didn't have anything in mind really. I was more looking along the lines of making something.

The citroen 2CV wheels are hub mount wheels. The only spindle mount wheels I've found attach to Mustang 2 suspension parts and those are pretty heavy for my application.

|

|